Detection of metallic objects

Metal detection is one of the most recognized methods for clearing bombs and mines in post-war areas. Even "plastic" mines should contain some amount of metal (according to international treaties).

For this purpose specialized metal detectors are commonly used. They have quite simple and robust design with an induction coil and processing electronics with the compensation of electromagnetic properties of difficult soils, so they can be very sensitive to even subtle metal pieces which are deeply buried in the ground.

However common metal detectors can indicate only the presence of an object, so each metal object has to be excavated as a potential mine. Scraps of metal are found hundred times more often than the actual mines, which makes clearing the mine-fields very slow.

Comparison of common metal detectors and devices with an array of magnetic field sensors

Can a metal detector be improved so it can recognize metal objects? There are multiple approaches to solve the problem (GPR, multi-frequency response analysis), in this case the solution is provided by multiple smaller sensors with a better spatial resolution. Using detailed scans of the natural or excited magnetic field of an object, the detector can recognize the shape of the object. Processing techniques allow to compensate for magnetic ground and determine material of the metal like in common metal detectors.

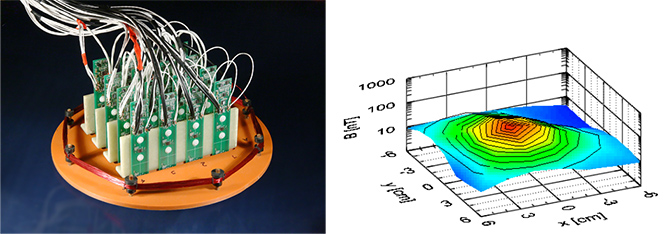

Metal detector with an array of AMR sensors and AC excitation (left), output with a 2-cm aluminum ring in 7-cm depth (right)

Related topics for diploma thesis:

- Direct processing of AMR sensor output by DSP

- PCB fluxgate with on-board electronics

- Metal detector with array of fluxgate sensors

Contact: jan.vyhnanek@fel.cvut.cz